True Wireless

Active Noise Cancellation

Acoustics

Digital Signal Processing

User Experience

Scroll down

Fujikon can accommodate any Bluetooth chipsets with our specially designed antenna, so that headsets can keep a well-established signal to smart devices within 15 meters or more at an adequate link margin and preserve an optimum setting on power consumption and product size.

Fujikon can accommodate any Bluetooth chipsets with our specially designed antenna, so that headsets can keep a well-established signal to smart devices within 15 meters or more at an adequate link margin and preserve an optimum setting on power consumption and product size.

True Wireless

Active Noise Cancellation

Acoustics

Digital Signal Processing

User Experience

Fujikon had developed a proprietary algorithm for both analog and digital ANC applications. With our own designed simulation program and Automated Testing Equipment (ATE), engineers can complete development and go into production with the highest quality and efficiency in the shortest period of time.

Fujikon had developed a proprietary algorithm for both analog and digital ANC applications. With our own designed simulation program and Automated Testing Equipment (ATE), engineers can complete development and go into production with the highest quality and efficiency in the shortest period of time.

True Wireless

Active Noise Cancellation

Acoustics

Digital Signal Processing

User Experience

With the simulation tool of speaker driver design, head and torso simulator on accurate measurement and recording, and advanced acoustic sensors for monitoring the acoustic changes, the Fujikon acoustic design team can develop superior headphones for that signature sound for our branded customers.

With the simulation tool of speaker driver design, head and torso simulator on accurate measurement and recording, and advanced acoustic sensors for monitoring the acoustic changes, the Fujikon acoustic design team can develop superior headphones for that signature sound for our branded customers.

True Wireless

Active Noise Cancellation

Acoustics

Digital Signal Processing

User Experience

The Fujikon research and development team keeps finding the right DSP solution to optimize headphones functions, minimize its power consumption, and miniaturize the overall product size.

The Fujikon research and development team keeps finding the right DSP solution to optimize headphones functions, minimize its power consumption, and miniaturize the overall product size.

True Wireless

Active Noise Cancellation

Acoustics

Digital Signal Processing

User Experience

Fujikon keeps researching technologies and uses owner experience to improve user satisfaction with our headphones. By implementing capacitive touch-sensing buttons, proximity distance detection, vibration sensing alert, beam-forming microphones for noise signal deduction, voice command, and waterproof design, etc., usability, accessibility, and pleasure have improved our products.

Fujikon keeps researching technologies and uses owner experience to improve user satisfaction with our headphones. By implementing capacitive touch-sensing buttons, proximity distance detection, vibration sensing alert, beam-forming microphones for noise signal deduction, voice command, and waterproof design, etc., usability, accessibility, and pleasure have improved our products.

True Wireless

Active Noise Cancellation

Acoustics

Digital Signal Processing

User Experience

Facilities

Information Technology

Mature information technology is essential for a well-established manufacturing company to minimize cost, control quality, and maximize production efficiency.

ERP

By implementing the SAP, ERP assists us to handle planning and management of Fujikon’s daily operation, which include sales order processing, supply chain management, and inventory and financial control. With this widest range of functionalities and reports, the Fujikon management team can review and make business decisions efficiently.

ERP

By implementing the SAP, ERP assists us to handle planning and management of Fujikon’s daily operation, which include sales order processing, supply chain management, and inventory and financial control. With this widest range of functionalities and reports, the Fujikon management team can review and make business decisions efficiently.

MES

Fujikon’s Manufacturing Execution Systems (MES) focus on product traceability control by monitoring and capturing real-time data on assembly lines, machines, and equipment. By analyzing the data, MES provides a real-time alert on the abnormality of production facilities, and the production team can take corrective action and implement a continuous improvement plan immediately.

Vertical Integration

Vertical integration allows Fujikon to increase supply chain efficiency, quality, and as a result, increased competitiveness.

Tooling Production

Injection Molding

Speaker Driver Production

SMT

Surface Finishing

Ear Cushion Production

1. TOOLING PRODUCTION

The Fujikon inhouse injection tooling shop tends to support customer product development by providing precision injection tooling with a high-quality standard in the shortest period of time.

2. INJECTION MOLDING

Equipped with diverse brands and models of plastic injection machines, Fujikon produces components in various qualities, tolerances, and specific process flow requirements. With sufficient equipment working with the MES, we can secure the peak seasons demand at maximum production efficiency.

3. SPEAKER DRIVER PRODUCTION

With Fujikon’s speaker driver production facility, engineers can apply customer acoustic performance requirements to the product effectively. In addition, our inhouse production capacity can secure supply chain demand in the peak seasons.

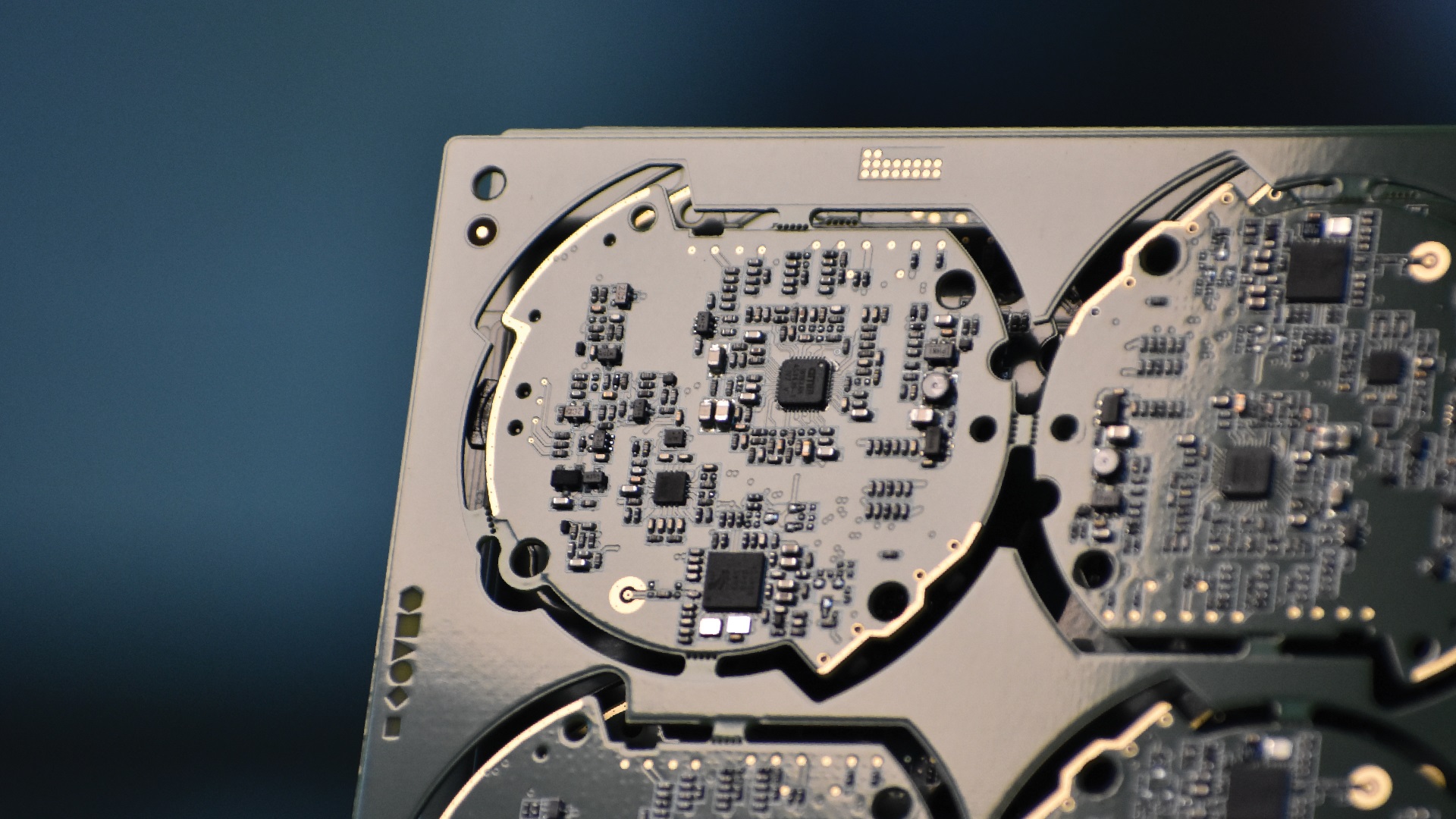

4. SMT

Miniaturization has become a trend in the consumer electronics market. With the most updated SMT facility installation, Fujikon can handle the SMD components in size 01005 and a BGA size of 0.3mm, which is the highest industry standard.

5. SURFACE FINISHING

Fujikon has built our own surface finishing production lines, which can fulfill most of the premium requirement of headphones such as a dust-free room, semi-automated spray painting, UV & rubberized coating, silkscreen printing, pad printing, hot stamping, and so forth.

6. EAR CUSHION PRODUCTION

By setting up our own ear cushion production facility, Fujikon built a professional team to support headphone development to determine the best ear cushion design from material selection to production. We also built proprietary equipment to inspect the acoustic performance of ear cushions as a headphone requirement.

Vision

To become our customers preferred strategic partner in the acoustics and electronics industries.

Mission

Through advancements in innovative technologies, we strive to provide value-added and distinct products to our customers.

About Us

Fujikon Industrial Co., Ltd.

A subsidiary of Fujikon Industrial Holdings Limited (incorporated in Bermuda with limited liability), 30 years worth of experience in OEM/ODM acoustic manufacturing business, from speakers to microphones to headphones, provided to airlines to now for well known brands worldwide.

Fujikon Packing Material Co., Ltd

Established in 1987, our company is one of the leading manufacturers in Hong Kong and South China, with well-established factory in Dongguan, PRC. Manufactures the most capable packaging in the industry, from vacuum-formed blisters to cushions for headphones, in the broad range of industries from electronics to cosmetics to food and toys. Our professional attitude and innovative designs provide trusts to many well known worldwide customers.

Fujikon Precision Metal Products Ltd.

Established in 1994, a subsidiary of Fujikon Industrial Holdings Limited (incorporated in Bermuda with limited liability), manufactures reliable metal products such as jacks for many worldwide customers. Our well-facilitated factory is also located in the well known city of manufacturing industry, Dongguan, quick service and convenience to our customers.

Milestones

Contact Us

Headquarter:

16/F, Tower 1, Grand Central Plaza,

138 Shatin Rural Committee Road,

Shatin, Hong Kong, China

Contact number:

+852-26055008

Email:

info@fujikon.com